A Novel Approach to Torrefaction

Torrefaction, Past, Present and Future

There has been a great deal of excitement over the prospects for torrefaction as a biomass pretreatment process. The advantages are obvious: high energy density, improved durability, hydrophobicity, and easy grindability are highly touted attributes frequently mentioned.

Although the strengths of torrefied biomass are tremendous, well recognized, and enumerated over and over again in publication after publication, the process of producing torrefied biomass has proved difficult. The weaknesses of current technology are obvious to those who have rolled up their sleeves and dived into the torrefaction process on a large scale.

As companies began to scale up from bench scale through demonstration to commercial scale, difficulties appeared. Torrefaction technology developers came to recognize the challenges associated with the technology, especially the possibility of fires, explosions, deposition of pyrolysis tars, etc. A common attribute of torrefaction causing significant problems is the explosive nature of the off-gases resultant from the torrefaction process. Several demonstration and commercial-scale plants have been built and then were destroyed because these off-gases were not dealt with adequately.

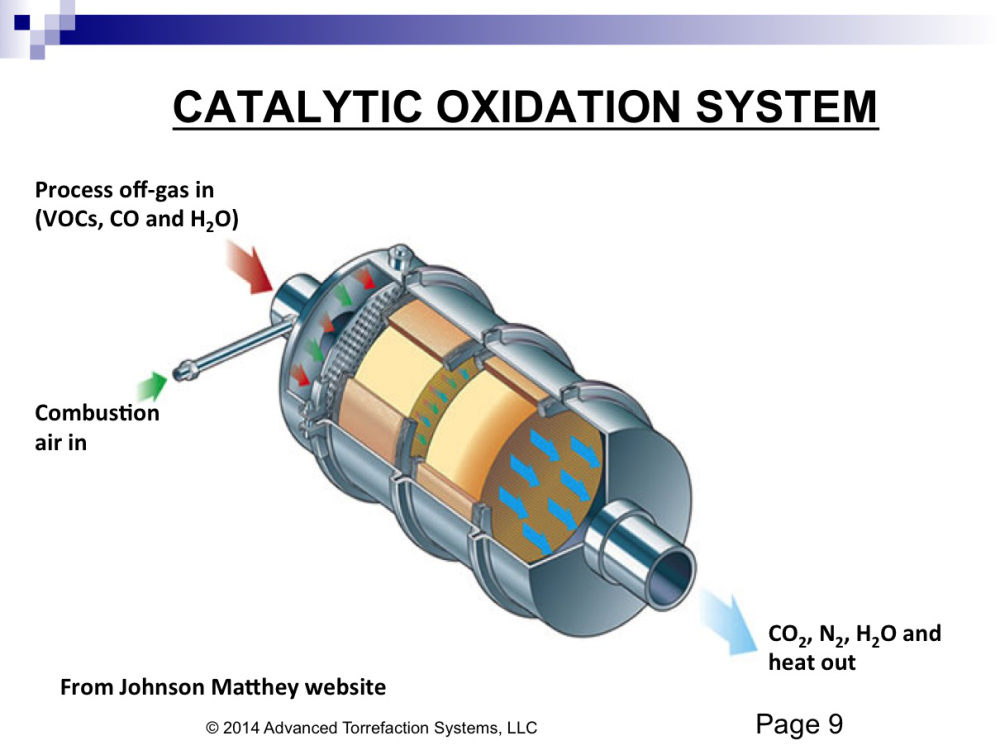

There is a solution to these dangerous gases – destroy them using an oxidation catalyst – with the added benefit that in the destruction of these gases, large volumes of SAFE inert gases are produced that can be used to purge the whole torrefaction system. Highly efficient, catalytic oxidation is the answer to safe and efficient torrefaction. We believe it is a game changer!

Advanced Torrefaction Systems, LLC (ATS) (www.atscat.com) is an alternative energy company based in St. Louis, Missouri, USA. ATS has developed ATS TorreCatTM Technology, a patented technology designed to solve some of the most significant problems that have hindered the development of commercial-scale torrefaction plants. Using an oxidation catalyst, ATS TorreCatTM

Advantages of ATS TorreCatTM Technology

- Destruction of the torrefaction gases from all system components results in a much SAFER process

- Heat for the process comes from the hot inert flue gases generated by catalytic oxidation

- No VOC-laden recycle loop is needed in direct-contact reactors

- The inert catalyst flue gases can be used as a VOC stripping gas in indirect-contact reactors

- The inert catalyst flue gases can be cooled and used for safe product cooling, fine grinding and densification

- Catalytic oxidation results in higher efficiencies and lower cost operations

- Catalytic oxidation can destroy VOCs at an efficiency rate of 99+%

- Low temperature catalytic oxidation results in the generation of essentially no NOx or CO

- A torrefaction system with catalytic oxidation requires less supplemental fuel; the supplemental burner is smaller and less expensive; and materials of construction for heat exchangers and duct piping for handling inert gas are much less expensive than for highly volatile torrefaction gases

ATS TorreCat™Technology: “THE GAME CHANGER”

Technology brings many benefits to the torrefaction process, including a level of efficiency well beyond the efficiency that can be achieved using a thermal combustion approach. The catalytic oxidation process safely destroys torrefaction gases and produces a low residual-oxygen (200-400 ppm), high temperature inert flue gas. This inert gas, comprised mainly of carbon dioxide, nitrogen, and steam, can be subsequently utilized as the heat source for both direct-contact torrefaction and pre-drying of the biomass feedstock. It can also be used as a VOC stripping gas for indirect-contact torrefaction. In addition, this same inert gas, when cooled, can be used in downstream processes such as direct-contact cooling, fine grinding and densification. The result is that all these steps benefit from an internally generated inert gas, thereby eliminating the expense associated with purchasing or generating those needed gases.

With ATS TorreCat™ Technology, the level of VOCs throughout all system components is significantly reduced, making the whole process safer. In addition, ATS believes that the reduced level of VOCs in the process results in a reduced level of VOCs in the finished product, thereby reducing the possibility of fires and explosions in transportation and storage.

IDAHO NATIONAL LABORATORY TESTING.

In February, 2016, the Idaho National Laboratory (INL) successfully performed demonstration testing with ATS TorreCatTM Technology. The INL Report can be accessed from a link found on our website at www.atscat.com.

ATS TORRECAT™ TECHNOLOGY CAN BE ADAPTED

TO ALMOST ANY EXISTING TECHNOLOGY!

ATS is now looking for a partner to help it demonstrate ATS TorreCatTM Technology at a larger scale and over a longer period of time than with the INL testing. Upon successful demonstration-scale testing, ATS TorreCat™ Technology will be ready for incorporation into a commercial-scale plant.

We believe that ATS TorreCat™ Technology is the safest, most energy-efficient torrefaction technology in the world.

For more information please contact:

Dan Herren, ATS President at 314.650.1186 US or by email at dherren@atscat.com, or

Tom Causer, ATS Vice President & COO at 814.598.2350 US or by email at tcauser@atscat.com